And there are no exact laws and regulations on baking paper in China. This situation leads to pits everywhere in the purchase of baking paper.

Learn about baking paper from the process and learn to buy baking paper. Don't let your brand reputation fall in the procurement link.

01

Basic uses of baking paper

Baking paper, also known as oil paper, is mostly called parchment in European and American countries. Baking paper is heat / oil / water resistant. It is the most commonly used baking tool in making cakes, biscuits and bread.

However, its structure is different from that of oiled or waxed paper. The silicon coating on its surface will not separate from the object it contacts until it is heated to 71 ℃.

In the conventional selection, baking paper can be roughly divided into three categories, and their properties are different. Please refer to the figure below in the purchase.

02

Safety analysis of baking paper materials

Breaking the pulp makes the wood fibers rearrange and have a certain strength, which is called coated paper. Finally, silicone is sprayed on it, which is the conventional process for manufacturing baking paper.

Manufacturers have a large choice of materials in the manufacturing of baking paper. The use of inferior materials will produce varying degrees of toxicity in the baking process and even in the links in direct contact with food, causing serious food safety problems.

The safety hazards caused by baking paper materials come from three aspects.

First, the selected baking paper substrate.

Parchment / translucent paper / high tightness and high smoothness overpressure kraft pulp paper are the most common substrates. However, no matter what kind of substrate, we need to choose baking paper made of base pulp. Base pulp paper uses biotechnology, so it does not add harmful additives such as bleach. And better toughness, not easy to break, good use experience.

Secondly, silicone coating is added to achieve its mild peeling resistance.

There are three types of silicone coatings at the present stage: solvent free > emulsion type > solvent type (safety comparison), among which emulsion and solvent free are the most popular manufacturing technologies abroad.

The most commonly used technology in China stays in solvent type. The stripping effect is very good and easy to use, but a large amount of solvent residue will be generated in the process of use, which is harmful to the environment and the health of production workers.

Third, improper addition of oil inhibitor to improve oil resistance.

Papermaking technology is a widely recognized way to improve the oil resistance of baking paper at home and abroad. The safest way is to improve the beating degree of paper (the speed of Pulp Filtration when making paper sheets on copper wire) and improve the hydrophilicity and plasticity of paper fibers.

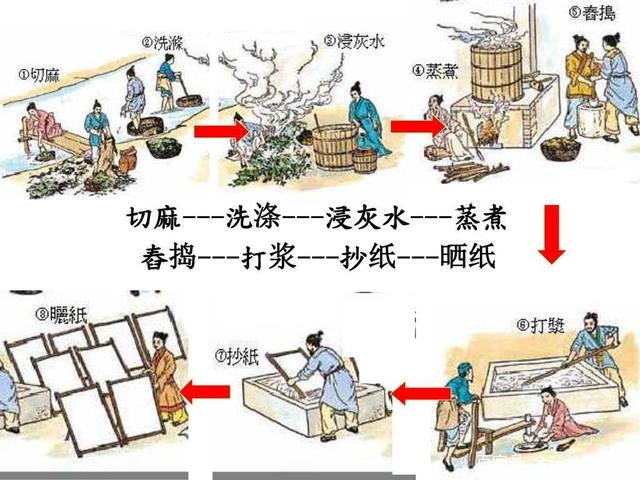

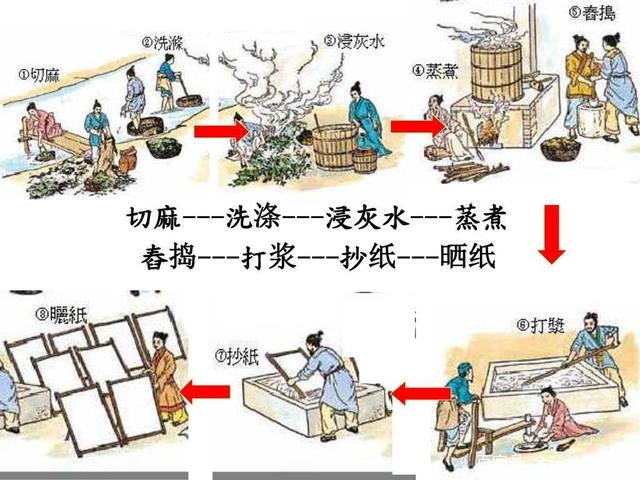

Simple schematic diagram of paper making process

The safety of adding oil inhibitor is worrying. So far, the practice of adding fluorine oil repellents is still not recognized by FDA (U.S. Food Safety Supervision and Administration). Other safe oil inhibitors have not been put into mass production.

Summary:

The qualified baking paper adopts the raw pulp + food grade silicone + solvent-free coating process.

For low-quality baking paper, the coating process of ordinary pulp + industrial grade silicone + organic solvent (toluene / xylene / gasoline / hydrogen halide) will be selected

03

Study on release of harmful substances from baking paper under high temperature environment

When baking paper meets the standard, does silicone have health hazards?

Polydimethylsiloxane (PDMS) was detected in food after high temperature, whether baking paper or silica gel baking molds

Polydimethylsiloxane structural formula

Siloxanes have different molecular structures, among which cyclic polydimethylsiloxane is used in baking paper. This substance is certified as inert and non-toxic, so users need not worry too much about it.

However, when using baking paper, it should be noted that the actual baking temperature should not exceed the maximum temperature prompted by the product packaging.

If the product does not have specific temperature instructions, it can be operated at a temperature not higher than 220 ° / 20min (Health Canada's temperature recommendations for silica gel products)

04

Selection of baking paper

There are two organizations with clear provisions on the food safety of baking paper:

One is FDA (food safety supervision and administration of the United States)

The second is BFR (German Federal Risk Research Institute)

China has no specific laws and regulations on baking paper, only the general regulations on food supervision materials. Therefore, when selecting baking paper, products with FDA or BFR certification are preferred.

For most domestic buyers, the vast majority of domestic products have not obtained relevant certification, and some even sell unqualified products in the name of import channels. In this case, the selection of advantages and disadvantages should not blindly follow the use experience, but give priority to the material labeling of products, and give priority to the products that meet China's food safety standards and basic quality inspection standards.

Article label: